Analysis of Printed Circuit Boards

Printed circuit boards (PCB) are an essential part of most electrical devices. They serve as carriers for electronic components and consist of an insulating plastic material onto which conductor tracks are integrated according to the circuit design. Electronic components are soldered in so-called soldering eyes or, today, usually as surface-mounted devices (SMD) on soldering surfaces (bond pads) of the circuit board.

There are many analytical questions connected with printed circuit boards that are regularly examined in the Tascon laboratory. Examples are questions about the base polymer that is used or the detection and distribution of flame retardants on raw circuit boards. However, the photochemical processes that are used for the series production of printed circuit boards can lead to issues where surface analysis is able to help. Impurities or residues from photoresists, etching solutions or surfactants can hinder subsequent steps in the production of printed circuit boards. The solder resists applied to printed circuit boards to control the solder flow and for mechanical and chemical protection can also run inhomogeneously, lose their appearance or unintentionally cover soldering surfaces (bond pads). Other typical analyses of circuit boards deal with the flow of flux, discoloration of the surface, corrosion processes, layer thicknesses of plated-through holes, dendrite formation on conductor tracks, the identification of particulate contamination or solder adhesion problems.

The last mentioned, inadequate adhesion of solder connections can often be analytically explained to unknown organic or elemental impurities, by faulty layer structures or unintentional diffusion processes on the surface of the metallic bond pads. In fact, these error patterns do not merely occur on printed circuit boards. They also turn up time after time on the surface of the bond pads of individual Si chips. Surface analysis methods such as SEM / EDX, ToF-SIMS or XPS play a particularly important role in the elucidation of these error mechanisms, as the following example shows.

Analysis of bond pads on printed circuit boards or chips

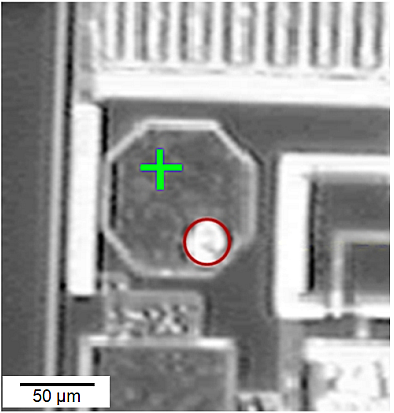

of a bond pad with light reflection (red circle,

analysis area 2) and reference position

(green cross, analysis area 1)

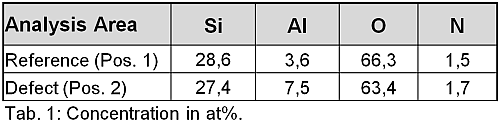

On a structured piece of wafer (die), a light reflex that was easily recognizable under the microscope was observed in the area of a bond pad (diameter: 100 µm) (see figure 1). To clarify the cause, small-spot XPS measurements were carried out in the area of this reflection (measurement point 2, MP 2) and an inconspicuous reference position (measurement point 1, MP 1). The analysis areas each had a diameter of 20 µm. The element compositions in the area of the reference point (MP1) and the defect area (MP2) could be determined quantitatively on the basis of the overview spectra created on these measuring spots. The results are shown in Table 1.

The comparison of the XPS data listed in Table 1 shows a local accumulation of aluminum as the cause of the optical disturbance. The quantitative composition of small surface areas provided by the XPS analysis was of decisive importance for solving the problem.

Tascon - your partner for the inspection of printed circuit boards

If you are interested in further details on the analysis of printed circuit boards, or if you would like to discuss a similar issue with us, please do not hesitate to contact us. We are happy to advise you personally about the analytical possibilities at Tascon.

The comparison of the XPS data listed in table 1 shows a local accumulation of aluminum as the cause of the optical disturbance. The quantitative composition of small surface areas provided by XPS analysis was of crucial importance to solve this problem.

Get in touch. Contact one of our analytical professionals:

(845)-352-1220