Analysis of Coatings

Protective layers on surfaces serve to maintain the properties of a surface, both functionally and optically. Sensitive surfaces can be found, for example, on electronic components and sensors, on medical products or membranes, on everyday objects and special tools and devices, both large and small. The coatings serve to protect the surface from aggressive media, to increase the biocompatibility, to improve the functionality or to function as a targeted barrier. The materials that are provided with a protective layer can vary. Depending on the area of application, these can be metals, plastics, glasses, semiconductors and others. The protective layers themselves can also be very different. We may be dealing with organic protective layers as well as inorganic coatings, all depending on the application or the expected environment. Not every protective layer is suitable for every function. Depending on the substrate, layer system, application and requirements for coatings, there are different methods for applying protective layers. These can be ALD processes, PVD or CVD methods, electroplating or a comparatively simple painting process.

All coatings or protective layers can fail. In some cases, a simple analysis shows that the layer itself has failed, as in the case of delamination, discoloration, corrosion and the like. Sometimes the failure of a component or product is observed where the cause is not directly or obviously attributable to the coating. In this case, a suitable analysis strategy helps. As soon as coating failure might be considered, it is good to contact a surface analysis laboratory. The case can be discussed with the experts, often even on site.

A number of methods for surface analysis are available in the Tascon laboratory. They each have special analytical strengths. Based on the sample system and the description of the problem, you will select the method that fits the analytical question and can best detect a possible error. Sometimes a combination of methods is required to analyze coatings. Targeted analysis of the coating and substrate is very helpful for quick diagnosis.

The following example from our laboratory shows the analysis of an organic protective layer.

Organic protective layers

coating of sensitive electronic components

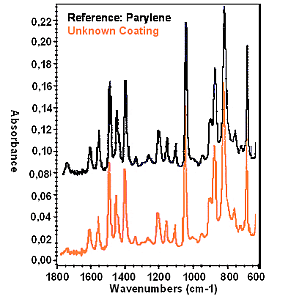

In the case shown here, a circuit board should be provided with a transparent protective film made of the polymer parylene for mechanical stabilization and as protection against corrosion. After component failures began to accumulate, the question arose as to whether the film, which was applied to the surface of the board and was several micrometers thick, was made of the desired polymer or had been replaced by an alternative product. To clarify this question, an ATR-FTIR analysis of the unknown protective coating was compared with the spectrum of a suitable parylene reference. The IR spectra shown show a clear agreement of all absorption bands. Parylene was thus clearly identified as a protective layer and an alternative coating as the cause of the failures could be excluded.

In the case shown here, a circuit board should be provided with a transparent protective film made of the polymer parylene for mechanical stabilization and as protection against corrosion. After component failures began to accumulate, the question arose as to whether the film, which was applied to the surface of the board and was several micrometers thick, was made of the desired polymer or had been replaced by an alternative product. To clarify this question, an ATR-FTIR analysis of the unknown protective coating was compared with the spectrum of a suitable parylene reference. The IR spectra shown show a clear agreement of all absorption bands. Parylene was thus clearly identified as a protective layer and an alternative coating as the cause of the failures could be excluded.

Tascon - your partner for the investigation of coatings and coating defects

Do you work with protective layers in your company and need expert advice? If you are interested in further details, contact the Tascon’s experts in the laboratory for the analysis and investigation of coatings on any material.

Get in touch. Contact one of our analytical professionals:

(845)-352-1220