Analysis of Contamination on Polymer Surfaces

Plastics are outstanding materials that can be adapted to their respective requirements in a wide variety of ways, both in terms of their shape and their function. The basic materials of plastics are organic macromolecules (polymers), which are composed of repeating units. The properties of polymers such as mechanical strength and hardness, stability at elevated temperatures, chemical resistance, light and UV resistance, wettability, sliding behavior, color etc. can be changed and optimized with the addition of various additives. In addition, the surface properties of plastics can be precisely adjusted by applying functional groups (functionalization). Functionalizations play a particularly important role in the refinement of the polymer’s surface properties, such as improving wettability or durability.

In our laboratory, we conduct analytical testing to answer a variety of analytical quesitons; including, efflorescence (crystalline deposits), problems with further processing, adhesion problems, questions about the degree of crosslinking of the polymer, residues from previous processes or external contamination, etc.

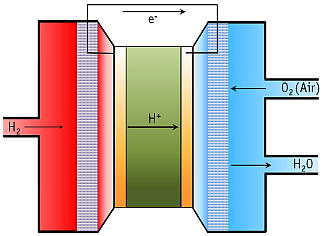

Contamination on polymer surfaces can disrupt (reduce) the surface functionalizations, interfer with the coating processes, and reduce the desired function of the plastic product. The following example illustrates how surface contamination can reduce the factionality of a polymer. XPS was used to analyze a defective membrane used in a solid polymer fuel cell (SPFC). The XPS analyses out at Tascon identified the source of the contamination in the transition from laboratory to small batch production.

XPS analysis of electrolyte membrane failure

In a series of experiments to optimize SPFCs, a sulfonated polyether ketone (sPEEK) was identified as a particularly suitable membrane. When switching production from laboratory to small batch production, however, the electrolytic properties of the sPEEK membrane used proved to be inadequate. Therefore, XPS analyzes were carried out to determine if the surface of the poorly performing small batch production membrane was contaminated. For this purpose, comparative XPS analyzes were performed on the laboratory production (reference) and the small batch production membranes.

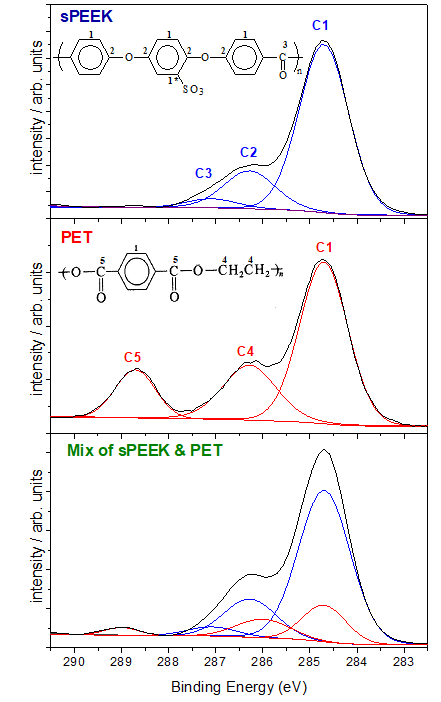

XPS analysis of the C 1s signal of an sPEEK reference and the small series membrane showed clear differences in the peak shapes, which indicated an external contamination of the surfaces. Further XPS analyzes showed that this contamination was polyethylene terephthalate (PET). The figure shows C 1s signals from an sPEEK (top) and a PET reference (center). The data show that PET can be clearly distinguished from sPEEK based on the COO signal (C5). From the quantitative analysis of the membrane's XPS data (figure below) carried out below, a PET coverage of the surface of approx. 10 % could be derived. A PET carrier film used in membrane production was identified as the origin of the PET contamination. The contamination problem could finally be solved by changing the material of the carrier film. A PET carrier film used in membrane production was identified as the origin of the PET contamination. The contamination problem could finally be solved by changing the material of the carrier film.

Tascon – Your partner for the analysis of contaminations

Tascon is your partner for the analysis of contamination on polymers and plastics. In addition to a variety of surface analysis techniques and years of experience, we also offer advice on all aspects of the analysis order, from planning the analysis to carrying out the surface analysis and discussing the results and their possible effects on your processing processes. Contact us and let us advise you without obligation.

Get in touch. Contact one of our analytical professionals:

(845)-352-1220