The Importance of Development Support in Your Company

Targeted surface and material analysis is a valuable building block for optimization and quality assurance along the entire product life cycle, from development through production to after-sales support (customer returns, error analysis). When [our services] are used in development support, there is enormous time and cost saving potential for our customers. Our analytical methods and expertise can help you optimize existing products; and, at the customer’s request, we are available for on-site visits during the improvement process.

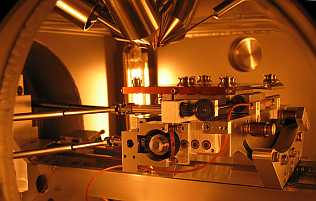

Development support and process optimization are customized to each company and product. Analytical support can range from simple surface analysis (ToF-SIMS, XPS, REM/EDX) to more complex depth profiles, layer analyzes, layer thickness determinations, as well as on-site inspections and discussions. This also includes a comprehensive study of literature and the use of experience from our network for development support. We at tascon are your partner for product development support.

Development Support is Worthwhile for Many Areas and Industries

Regardless of the area and industry in which you or your company operate, development support can be a useful tool to take your business to the next level. Our development support has already been successful in the following areas:

- Glass Industry:

Optimization of a coating by adjusting the process parameters. The ToF-SIMS depth profiling is mainly used here, which has good depth resolution and is very sensitive to minor changes in the chemical composition. - Wetting, Liability, Adhesion

ToF-SIMS spectrometry of affected surfaces can usually be used to quickly decide whether e.g. organic foreign contaminants (greases, silicones, silicone oils, plasticizers) are present or are introduced via the process and the production environment. Techniques such as LEIS, XPS and REM / EDX are available for inorganic contamination. In these cases, development support also means that we investigate possible contamination routes with our customers during a site inspection. If necessary, we also refer other experts (cleaning specialists, QM and process experts). - Metal Processing Industry:

A change of the end product range made it necessary to completely redesign the coating formulation. In addition to SEM/EDX analyzes to determine the layer composition and errors in the coating process (blasting process, application of a primer, temperature control when applying the coating, handling of the end product by the user), the determination of the total layer thickness (DFT, dry film thickness) was also of crucial importance. At the end of the process optimization and development support, the elaboration of quality specifications to be observed by the coater and specifications for incoming material checks was completed. On-site customer visits were carried out in order to get a better understanding of the customer’s production enviroment. - Pharmaceutical Industry:

Problems associated with scale-up often arises here, i.e. a product can be easily manufactured in small series, but there are manufacturing errors on the large system. In the case of a tablet production, it was necessary as part of the development support to take samples directly on site (site inspection) and to regularly compare the analytical results with the development specifications and the results of small batch series.

Request Development Support Now

Regardless of whether you find yourself in the list of proven companies that have already benefited from development support or otherwise see the potential for development support in your company - we will be happy to advise you on all your inquiries in the field of development support. If you are interested in development support, please contact us. We look forward to your inquiry.

Get in touch. Contact one of our analytical professionals:

(845)-352-1220