Analysis of Polysiloxane (Silicone, PDMS) on Surfaces

Polysiloxanes Cause a Variety of Failures in Surface Processing

Polysiloxane - also called silicone or silicone oil - is a synthetic polymer based on silicon. Because of its outstanding physical and chemical properties and its universal applicability, it can be found in many everyday goods. For example, the cosmetics industry uses polysiloxane as an additive in hand creams, body lotions, shampoos and soaps to make the skin or hair appear smooth. In the laboratories of the chemical industry, polysiloxane is used as a mold release agent, lubricant, plasticizer, emulsifier or as a defoaming agent. Many of these applications are made possible by the very low surface tension of polysiloxanes. Due to this low surface tension, polysiloxanes have a tendency to migrate to surfaces and interfaces. This is the reason why they, for example, prevent the foaming of paint formulations. This low surface tension is an extremely useful property of polysiloxanes. However, it can prove to be a disadvantage in adhesive and coating processes.

Contamination with polysiloxane is often the cause of discoloration, wetting problems and adhesion failure on metals, plastics and polymers as well as contact problems with electronic components. Even the smallest concentrations can lead to massive disturbances in sensitive systems. Due to its widespread use in a variety of processes and formulations and due to its low surface tension, polysiloxane is one of the most common surface contaminations. This makes the analysis of polysiloxane of particular interest for surface analysis. The following questions arise when it comes to coating problems:

Can a polysiloxane be detected on the surface?

We have Time-of-flight secondary ion mass spectrometry (ToF-SIMS) available in our laboratory. It is an excellent analytical method for the detection of polysiloxane (silicone oil, PDMS). With a detection limit in the ppm range, the method offers significantly higher sensitivities than other detection methods (e.g. IR spectroscopy). Even the smallest, process-damaging quantities can be detected with this type of analysis.

How much polysiloxane can my process tolerate?

In answering this question, the semi-quantitative information from the ToF-SIMS is combined with suitable tests on the adhesion behavior (e.g. cross-cut of coating layers). The bar chart opposite shows an example of the relationship between a semi-quantitative determination of the polysiloxane coating on steel surfaces and the color-coded results of an adhesion test after coating (good adhesion: green, poor adhesion: red). In the analyses in our laboratory, polysiloxanes were detected on all samples. By comparing the references (R. 1 and 2) with the bad samples A to C, a limit value for polysiloxane could be determined that does not negatively influence the adhesion in the subsequent process. Based on this, the polysiloxane contamination of new steel batches was determined and evaluated in a standardized procedure using a traffic light code.

What more can our laboratory tell about polysiloxanes?

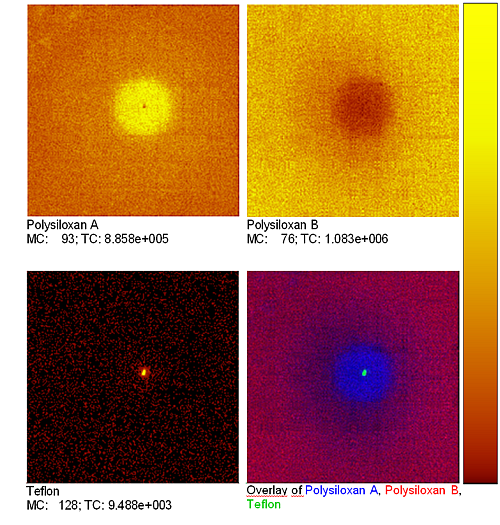

The polysiloxanes form a class of polymers. In addition to the determination of the amount of polysiloxane, the ToF-SIMS available in our laboratory also allows the differentiation between the different types of polysiloxanes. This is illustrated by the image (chemical map) on the right, showing the lateral distribution of various organic components that were detected in the area of a paint crater. The surface of the paint contains a modified polysiloxane B, which is displaced by a second polysiloxane A in the area of the crater. In addition, a Teflon particle is found in the crater. Both Teflon and the polysiloxane A are incompatible with the coating system. They change the wetting properties and thereby lead to crater formation.

The polysiloxanes form a class of polymers. In addition to the determination of the amount of polysiloxane, the ToF-SIMS available in our laboratory also allows the differentiation between the different types of polysiloxanes. This is illustrated by the image (chemical map) on the right, showing the lateral distribution of various organic components that were detected in the area of a paint crater. The surface of the paint contains a modified polysiloxane B, which is displaced by a second polysiloxane A in the area of the crater. In addition, a Teflon particle is found in the crater. Both Teflon and the polysiloxane A are incompatible with the coating system. They change the wetting properties and thereby lead to crater formation.

Tascon - your partner for the analysis of polysiloxanes on surfaces

Do you need our support for the analysis of polysiloxanes? Then contact Tascon and let us advise you without obligation.

Get in touch. Contact one of our analytical professionals:

(845)-352-1220