Glass Analysis

Composition, Contaminations, Coatings

In the last few decades, glass has developed into a true high-tech product. The use ranges from comparatively simple spectacle lenses for the end consumer to doped lenses in optoelectronics to coated special lenses in the solar power industry. With the availability of a large number of additives, many glass properties can be adjusted almost at will. Characteristics such as glass hardness, refractive index, tensile strength, fracture toughness, thermal properties or electrical properties can be adjusted by adding different additives. Examples of glass additives are: potassium oxide, zinc oxide, barium oxide, tin dioxide, calcium phosphate, zirconium dioxide, aluminum oxide or cerium oxide. Apart from the use of different additives, coatings such as metallization can also indirectly influence the properties of the glass. Glass coatings are often used to optimize physical parameters such as reflection, transmission or thermal insulation properties. The coating forms a precisely defined layer system, made up of adhesive, functional, protective and various intermediate layers. In the Tascon laboratory, the analysis of glass has been part of our diverse range of tasks for more than 20 years. High-performance methods for the analysis of glass include X-ray fluorescence analysis (XRF), time-of-flight secondary ion mass spectrometry (ToF-SIMS) and X-ray photoelectron spectroscopy (XPS). Below you will find a selection of the analyses we have carried out. If your question is not among those listed, please do not hesitate to contact us and contact Tascon. Our employees will find a tailor-made solution to your problem.

Analysis of the composition of glass

Due to the complex composition of glasses, the identification of individual recipe components of the bulk material or the elemental composition are often of particular interest. The ToF-SIMS technique that is used in our laboratory enables the detection of sample components such as dopants with the help of a depth profile. With appropriate standards, these can be quantified. In addition, an analysis with XPS analysis enables a comparatively quick quantitative determination of the elemental composition of glasses. The selection of the suitable method must be adapted to the relevant question. Tascon’s staff will be happy to advise you on this.

Analysis of glass contamination

In addition to the intended addition of substances to a glass recipe, involuntary impurities may be introduced in the manufacturing process. This contamination can be present in the form of particles that are trapped in the glass or contamination that is on the surface of the glass. Both types of contamination can affect the properties of the glass. An analysis with ToF-SIMS can detect both molecular and elemental impurities..

Analysis of coatings on glass

The analysis of the layer structure, identity and composition of a coating system can be carried out in our laboratory with the help of various techniques. It does not matter whether it is an organic or inorganic coating. ToF-SIMS is an excellent tool to clarify layer systems on glass because of its depth profiling capability. A few nanometers in a small area of the sample are removed by an ion beam and this area is then imaged. This process is repeated and the stack of image leads to a three-dimensional image of the sample. Another technique available in our laboratory for layer elucidation is XPS. With the help of XPS, for example, elements in layers can be quantified and the corresponding oxidation states determined. XPS analysis of glass also enables the analysis of a surface treatment or a surface functionalization.

Tracking down a Common Corrosion Mechanism

Glass Corrosion

Glasses that are exposed to moisture for a long time, for example due to the weather, can corrode. Progressive glass corrosion can be recognized by a white veil or by iridescent, shimmering films on the glass. Many substances that act on the glass in a moist environment can cause or accelerate glass corrosion. Examples include pollutants from the air such as sulfur and nitrogen compounds, alkaline substances from concrete leaching or organic components that diffuse from sealants.

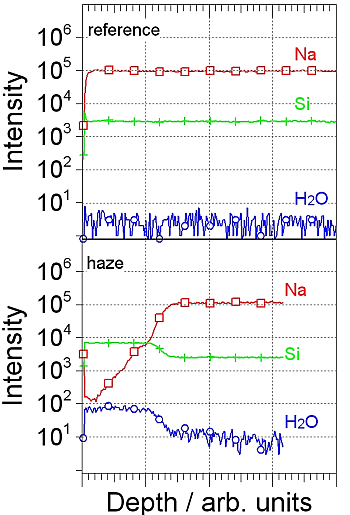

ToF-SIMS depth profiling of a glass with a matt veil reveals the typical changes in the material due to glass corrosion (lower depth profile). Compared to the undamaged glass reference (upper depth profile), a loss of Na and K in the near-surface region is evident, which is associated with an increased concentration of water. Na ions in the glass are exchanged by H ions. This destroys the structure of Si, Na and O which leads to roughening of the surface on a micro-scale. This changes the visual appearance of the glass surface. Due to the high element sensitivity of ToF-SIMS depth profiling, glass corrosion can easily be separated from other changes in the surface, e.g. deposits on the glass.

Tascon - your partner for the analysis of glass

Tascon is your competent partner laboratory for all questions on the analysis of glass, glass surfaces, glass coatings, and all failures concerning glass surfaces. If you need support in analyzing glasses, please do not hesitate to contact us. Our friendly and competent team looks forward to your inquiry and will be happy to advise you personally and without obligation.

Get in touch. Contact one of our analytical professionals:

(845)-352-1220